𝗣𝗿𝗼𝗱𝘂𝗰𝘁 𝗗𝗲𝘀𝗰𝗿𝗶𝗽𝘁𝗶𝗼𝗻

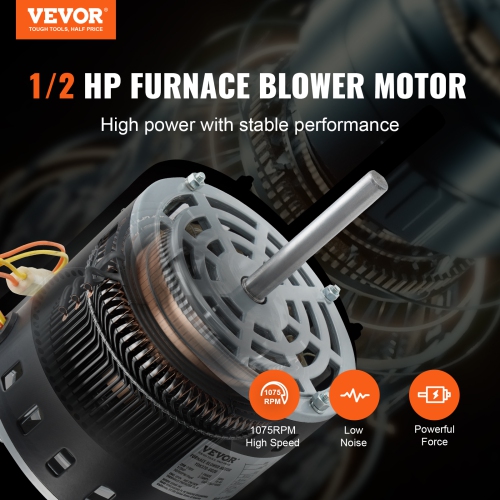

· 1/2HP Furnace Blower Motor

208-230V voltage, 2.7A current, 48 frame size, 3.4" shaft length, 0.5" shaft diameter, CW/CCW dual rotation, with 7.5μF/450V capacitor, 11" hold hoop.

· Convenient Accessories

Specially equipped with additional accessories (CBB65 7.5μF/450V capacitor & 11-inch hold hoop), eliminating the need to worry about choosing compatible components separately.

· Durable Material

Furnace blower motor casing is made of durable metal material, with strength, reliability, excellent durability, and high corrosion resistance.

· Dual Rotation

Achieve the perfect direction every time with the versatile CW/CCW dual rotation capability.

· Wide Applications

Suitable for residential air conditioning duct units and heaters (with the motor inside the fan blade), capable of meeting various household area requirements.

· 7.5μF/450V Capacitor

Prevent issues such as short lifespan, overheating, and motor startup failure caused by old capacitors.

𝗦𝗽𝗲𝗰𝗶𝗳𝗶𝗰𝗮𝘁𝗶𝗼𝗻𝘀

Voltage: 208-230V

Horsepower: 1/2HP

Rotation Speed: 1075RPM

Number of Speeds: 5

Frequency: 60Hz

Frame Size: 48

Rated Current: 2.7A

Shaft Length: 3.4"

Shaft Diameter: 0.5"

Rotation: CW / CCW

𝗣𝗮𝗰𝗸𝗮𝗴𝗲 𝗖𝗼𝗻𝘁𝗲𝗻𝘁

1 x 1/2HP Furnace Blower Motor

1 x 7.5μF/450V Capacitor

1 x 11-inch Hold Hoop

1 x Instruction Manual

Ensure the horsepower(HP) and the specifications on the nameplate for a precise match. It is important to match the required horsepower and specifications for your motor. Installing a lower horsepower motor can result in overheating and improper functioning. While the replacement parts are compatible with major brands, always verify the fitment with your specific application.

· 1/2HP Furnace Blower Motor: This motor has a power rating of 1/2 HP and operates at 1075 RPM with 5 different speeds. It requires a Full Load Amps of 2.7A and operates on a power supply of 208/230V. It is designed for direct-drive blower motors used in residential and light commercial indoor furnaces, air handlers, and packaging systems.

· Frame Type: The motor belongs to the 48 Frame Size category and features a 0.5" shaft diameter with a shaft length of 3.4". It operates with strong and powerful performance, running at high speed while maintaining low noise levels.

· Safety and Durability: The motor is housed in a sturdy metal casing that exhibits high strength and corrosion resistance. This robust construction effectively protects the engine, ensuring a longer service life.

· Convenient Accessories Included: The motor comes with convenient accessories, including the CBB65 7.5μF/450V capacitor. This capacitor helps prevent issues such as a shortened lifespan, overheating, and motor startup failure caused by an old capacitor. Additionally, an 11-inch hold hoop is provided as an installation bracket, reducing the need for additional mounting hardware purchases.

· Dual Rotation Direction: The motor is reversible, allowing for both clockwise (CW) and counterclockwise (CCW) rotation. This feature makes the installation process much easier. It is suitable for air conditioning duct systems and furnaces in homes of various sizes, effectively circulating cool or warm indoor air.

· Tools Needed: (not included in the package)

Drill Set - Most common are Phillips, 1/4, and 5/16 fittings.

Flat Head Screw Driver - Help pry things apart and get leverage when needed.

Pliers - Help pull things off such as terminal leads.

Wire Strippers/Cutters - To adapt and strip wiring to match up to your unit's specs.

Wrench - For loosening and tightening bolts or set screws.

Measuring Tape -Make sure you position the fan blade correctly on the new motor.

Multi-Use Lubricant Spray - Loosen up all those years of use.

Voltage Meter - Help you make sure power is off and items are disengaged before servicing.

Capacitor-Discharge Pen Or Electrical Grounded Screw Driver - This is what you can use to disengage the capacitor.

Fan Blade Puller - You most likely will need this as most fans have been on units for years and are stuck on there like glue.

Sawzall Tool or SDSB100 Shaft Blaster - In some cases, you need to cut the shaft down to match the original or cut the shaft to the old motor to get it off.