𝗣𝗿𝗼𝗱𝘂𝗰𝘁 𝗗𝗲𝘀𝗰𝗿𝗶𝗽𝘁𝗶𝗼𝗻

· VEVOR 3-In-1 Sheet Metal Brake

Our sheet metal machine combines rolling, bending, and shearing functions into one compact unit. It allows you to adjust the roller position with a knob, extend up to 90 degrees, and cut through various sheet materials.

· Robust & Durable Materials

Crafted with care to be your enduring workhorse. This shear press brake is built with carefully selected materials to deliver optimal performance. Industrial-grade materials ensure durability and resistance to wear, ensuring a long lifespan.

· Detachable Modular Design

The upper bending tool and lower die module are constructed from sturdy 0.2-inch/5 mm thick #45 material. It comes with five different-sized blades: 1", 2 x 2", 3", and 4", ensuring effortless bending of low-carbon steel and aluminum.

· Craftsmanship Versatility

The roller of our sheet metal brake is equipped with precise curvature adjustment technology, allowing you to effortlessly create a wide array of cylindrical and tapered workpieces and result in flawlessly smooth sheet metal.

· Meet Your Processing Needs

Our 3-in-1 combination sheet metal machine enables you to easily handle various sheet metal processing requirements and supports sheet materials with 20 GA / 1 mm Max. Thicknesses, 12 in /305 mm Max. Width and also offers a 90-degree bending angle.

· Easy to Operate

Operating our sheet metal brake press is a breeze. Requires no cumbersome training or specialized knowledge. There's no need for extra accessories or components. Users can quickly grasp the operational techniques, enhancing work efficiency.

𝗦𝗽𝗲𝗰𝗶𝗳𝗶𝗰𝗮𝘁𝗶𝗼𝗻𝘀

Item Model Number: 3-in-1/305

Max Shearing Length: 12 in / 305 mm

Max Shearing Thickness: 20 GA / 1 mm

Blade Clearance: <0.07 mm

Shearing Tensile Strength: ≤235 MPa

Max Bending Thickness: 20 GA / 1 mm

Max Bending Width: 12 in / 305 mm

Max Bending Length: 28 in / 710 mm (±10mm)

Max Bending Angle: 90° ± 1°

Max Sheet Rolling Width: 12 in / 305 mm (±3mm)

Roller Working Length: 12 in / 305 mm (±3mm)

Sheet Rolling Thickness: 20 GA / 1 mm

Min Sheet Rolling Diameter: 1.8 in / 45 mm

Surface Treatment and Color: Painted

Primary Materials: Q235, 45#, HT200

Net Weight: 90 pounds / 41 kg

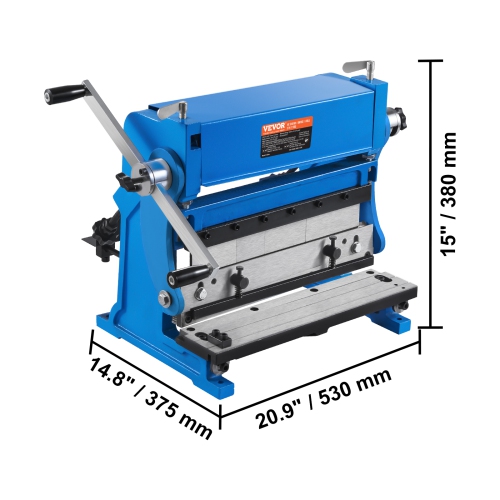

Product Dimensions: 20.9 x 14.8 x 15 in / 530 x 375 x 380 mm

Shearing Blade: Thickness: 0.4 in / 10 mm, Length: 14 in / 354 mm, Width: 0.8 in / 20 mm, Hardness: 52 HRC; Material: T10

Upper Bending Tool: Straight Blade, Thickness: 0.2 in / 5 mm, Length: 12 in / 307 mm, Width: 2.3 in / 58 mm, Hardness: 21 HRC; Material: 45#

Lower Bending Die: V-shaped Die, Thickness: 0.8 in / 20 mm, Length: 13.8 in / 350 mm, Width: 2.5 in / 63 mm, Hardness: 21 HRC; Material: 45#

Sheet Rolling Drum: Diameter: 1.5 in / 38 mm, Length: 12 in / 305 mm, Hardness: 21 HRC; Material: 45#

𝗣𝗮𝗰𝗸𝗮𝗴𝗲 𝗖𝗼𝗻𝘁𝗲𝗻𝘁

1 x Sheet Metal Brake

1 x User Manual

· All-in-One Functionality: Our 3-in-1 combination sheet metal machine offers the functions of a bending machine, shearing machine, and rolling machine all in a single unit. Say goodbye to the hassle of purchasing multiple independent machines and the tedious switching process. It is a must-have for your factory and workshop, enhancing overall work efficiency.

· Exceptional Compatibility: Our sheet metal brake supports sheet materials with a 12 in/ 305 mm Max. Width and 20 GA / 1 mm Max. Thickness. With 90° Max. Bending angle and a blade clearance of less than 0.0027 in/0.07 mm provides a wide range of options for your processing tasks.

· Robust Construction: This shear press brake features HT200 material casting built to last. The shearing blade is made of T10 material, cutting without burrs. Both the bending blade and the roller are constructed from 45# material, offering exceptional durability and resistance to deformation. It easily processes low-carbon steel, aluminum, brass, copper, lead, plastic, zinc sheet metal, etc.

· Segmented Bending Versatility: The central bending module of our sheet metal brake press includes five blades with sizes of 1", 2 x 2", 3", and 4".You can customize blade combinations based on your requirements to carry out a wide range of complex sheet metal processing tasks, such as manufacturing exterior wall panels for houses, doors, and window materials. It is widely used in homes, factories, and small workshops.

· Precision Processing: Utilizing advanced external cylindrical grinding technology, our 3 in 1 combination sheet metal machine reduces friction between the sheet metal and rollers, enhancing machine stability during operation. It also minimizes scraping caused by uneven roller surfaces, improving sheet metal surface smoothness.